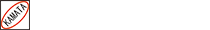

Quality Assurance System

By advocating a product quality policy for our customers to be happy, we strive to improve in the quality of our products on a day to day basis. We assure our products fits our customer’s needs, by means of offering appropriate product information based on related laws and regulations, applying GMP for the purpose of ensuring the quality and safety of our products, quality assurance activities such as inspecting the material suppliers and quality control activities such as testing the products are standardized.

Product Quality Policy

For all our customers to be satisfied, we offer a product with high quality, low price, safe and secure. In order in doing so, we have set the following goals.

1. To achieve the product quality policy, each department will set a goal for product quality and disseminate it.

2. We sincerely listen to our customer’s voice, putting first their whished product quality.

3. With a healthy mind and body and always with a bright smile and greetings, we strive to improve our skills.

Quality Control Activities

①Tests are done by confirming the safety of the material by microorganism test, verifying the materials are according to standard by checking the appearance and the evaluation documents.

②The products made with the materials which passed the acceptance test are inspected between processes according to its characteristics. These are the intermediate product inspections. These inspections will check the size, weight and moisture value and decides whether or not it can go on to the next process.

③Rigorous tests concerning various product qualities and safety such as size, weight, disintegration test, moisture value and for microorganism tests are done as product tests.

④The products which passed the product tests are packaged in an appropriately controlled process and the final products are comprehensively tested.

⑤Judging comprehensively by the results from all the tests and from the production processes, we decide whether or not to proceed with shipping.

⑥The approved products are shipped to a location our customers request. If our customer wishes, we perform a stability test which makes sure of the stability of the products.

Quality Assurance Activities

Product Standard Documents

The product standard documents contain information about the product manufacturing such as the material, proscription, mixture, manufacturing process and the product tests conducted. A number of checks are done to ensure the document is written based on correct information, and when there is a change in the content we revise it without delay, maintaining it accurate at all times.

Coping With Relating Laws and Regulations

We keep track of every move in agencies such as Consumer Affairs Agency and the Ministry of Agriculture, Forestry and Fisheries, accurately understanding the administration concerning food, and managing a system which can promptly reflect any change in laws to our product.

Standards and Certification

Toke factory of Kamata Co. Ltd. is a GMP Certified Factory by the Japan Health and Nutrition Food Association. The objective of GMP is to ensure the quality and the safety of a product by constructing an appropriate management system and executing work management (quality control, work control) and by constructing an appropriate facility. Also, to aim to provide safe food to our customers, we acquired FSSC22000 certification, an internationally recognized food safety management system for Toke Plant in August 2022.

Supplier Inspections

The quality assurance department visits the factories of our suppliers and make inspections to ensure appropriate materials are being delivered.

<Examples of Inspection Items>

・ The initiatives regarding procurement, manufacturing and the product quality such as the storage condition of the materials, various conditions during manufacturing, appropriate managing of chemicals and sanitary survey.

・The status of the system to offer safe and appropriate food, by equipping specification documents of the product and its producing methods.

・The status of readiness for emergencies, such as the response regulation and the channel of communication when accidents and incidents occur.

Employee Education

The product assurance department takes the lead in the educational work for all employees, mainly of food safety and hygiene, but also carries out the education with the improvement of knowledge and awareness in mind. We also strive to advance our knowledge, awareness and skill by making each employee initiatively take part in shearing information such as the requests from customers which is done in each department, in optimizing work efficiency and in quality improvement activities, reflecting them in every day production.

Hygiene Management

・Cleanliness Classification

Inside of the factory is divided into 3 areas according to its cleanliness. We make our products by paying extra attention to hygiene. Each area has different colored working clothes, and trafficking between these areas is forbidden.

・Cleanliness Class 1

Cleanliness Class 1 is the production area with the highest cleanliness. This is the area that a worker may come into direct contact with the product during the process such as measuring the weight of the materials.

・Cleanliness Class 2

Cleanliness Class 2 is the production area where the intermediate inspection for the outward appearance is done, and where the final product is completed by being packaged.

・Cleanliness Class 3

Cleanliness Class 3 is the area where the observation paths, offices, dining hall and meeting rooms are located.

Here, the visitors are permitted to move around in plain clothes.

・Air Pressure Control

The air pressure in the production area is controlled to be positive, higher than that of the area outside. It is controlled so that outside air or dust will not come in through the gaps between walls and ceilings. The air is also designed to flow from the area with higher cleanliness class to the lower, thus making contamination hard to occur.

・The Process of Entering

There are changing rooms which are designated for each area of cleanliness classifications. Also, for the area of cleanliness class 1 and 2, the way of dressing and the entrance to the production area are different. To enter into the area of cleanliness class 1 with the highest hygiene, you must go through a primary changing room, primary hand washing room, secondary changing room, secondary hand washing room and an air shower.